A Glimpse into the Past: The Historical Significance of Redstone Coke Ovens

The Redstone Coke Ovens stand as silent witnesses to a bygone era. Tucked away in Colorado’s serene mountain landscape, these dome-shaped structures speak volumes of an industrial age. We trace their origins to the late 19th century, a time when the demand for steel spurred the need for high-quality coke. The ovens’ purpose was clear and vital: transforming coal into coke for iron ore smelting.

Built in 1899 by Colorado Fuel and Iron, these ovens were pivotal to the region’s economic growth. They operated at the heart of a flourishing industry, churning out pure carbon. This coke then made its way to Pueblo, fueling blast furnaces and steel production. However, like many industrial marvels, their significance dwindled with technological advances and market changes. By 1909, the need for coke had decreased, leading to the suspension of coking operations.

Yet, the Redstone Coke Ovens are more than relics. They symbolize the intersection of ingenuity and the natural resource boon of the West. Their historical significance lies not just in their function, but also in the legacy of industrial innovation they represent. They remind us of a time when coal and steel were kings, shaping not only the physical but also the economic landscape of the area.

Today, they continue to draw visitors, not only for their architectural uniqueness but also for their role in the tale of America’s industrial journey. As we explore these structures, we are transported to a pivotal moment in history, giving us a glimpse into the industrial past of Western Pennsylvania and Colorado.

Architectural Marvels: The Design and Structure of the Coke Ovens

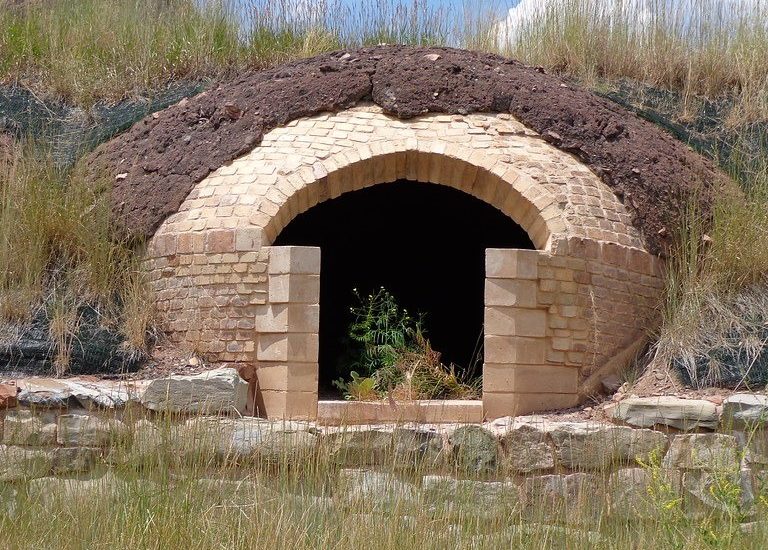

The Redstone Coke Ovens are a true spectacle in architectural and structural design. Built in 1899, these ovens were uniquely designed to withstand extreme temperatures, essential for converting coal into coke.

Unique Dome-shaped Design

The dome shape of each oven is not just visually striking but also functionally pivotal. This shape allowed for even distribution of heat inside the oven, reaching temperatures up to 2,400 degrees Fahrenheit. The ability to sustain such high temperatures was critical for the coking process, ensuring that all impurities were effectively burned off.

Built with Heat-resistant Materials

The construction materials chosen for the Redstone Coke Ovens were no ordinary picks. They had to resist not only high heat but also continuous use over long periods. Materials such as refractory bricks were used, made to endure the harsh conditions within the ovens.

Strategic Layout

Strategically placed in Redstone, Colorado, the layout of the coke ovens was meticulously planned to take advantage of the local resources and transport routes. Being in proximity to coal mines and close to rail lines for shipping was essential for operational efficiency.

The architectural ingenuity of these ovens is a testament to the era’s technological advancement and industrial need. Even today, they impress visitors with their resilience and historical significance in turning raw coal into a vital component for steel production.

From Coal to Coke: The Coking Process Explained

Turning coal into coke involved a complex process, crucial for steel production. Let’s delve into the steps that transformed coal—loaded with impurities—into high-quality coke, an essential ingredient for iron smelting.

First, workers loaded coal into the Redstone coke ovens. The dome-shaped design guaranteed a tight space. This contained heat effectively during the coking process. The ovens would then be sealed, except for small air vents. These vents played a significant role, allowing limited oxygen to fuel the combustion needed to heat the coal.

As temperatures inside soared up to 2,400 degrees Fahrenheit, something remarkable happened. The intense heat gradually eradicated the coal’s volatile compounds. These included substances like sulfur and tar. The process took around 48 hours to complete, and constant supervision assured quality and safety.

Once the coking cycle concluded, the heat was extinguished, and the coke cooled down. This involved opening the ovens and dousing the hot coke with water. The sudden temperature change made the coke hard and porous. This porous nature was ideal, increasing the surface area for the blast furnaces later.

Finally, the coke was extracted from the ovens. Sturdy tools broke it into manageable sizes. The coke was then shipped to the Colorado Fuel and Iron facilities in Pueblo. There, it played a pivotal role in the production of steel.

The ingenious design of Redstone coke ovens made this effective transformation possible. Each step illustrates human innovation in harnessing natural resources for industrial growth. Today, the Redstone coke ovens stand as a testament to this influential industrial procedure that shaped American industrial history.

The Heyday of Coke Production in Western Pennsylvania

The Redstone coke ovens recall a time when Western Pennsylvania was a titan in coke production. Beginning in 1817, the area boasted the largest coke oven facilities in the United States. These sites transformed countless tons of coal into pure carbon for the steel industry.

During this peak period, coke was a key ingredient in steelmaking. It fueled the massive blast furnaces that powered America’s industrial revolution. Towns like Redstone flourished, with mines and ovens operating around the clock. The process was straightforward but pivotal—miners extracted coal, workers baked it in ovens, and the results boosted steel production.

Such intense demands led to technological innovations and large-scale operations. Workers and machines worked in unison, improving both the quality and quantity of coke produced. Railroads expanded to support the industry, connecting remote ovens to bustling steel mills.

This period also saw the growth of key companies like Colorado Fuel and Iron. They linked the fortunes of Colorado and Western Pennsylvania, turning resources into economic strength. The coke produced in Redstone helped fuel their Pueblo steelworks. Despite this shared heritage, each region had its unique mark on history.

The heyday of Western Pennsylvania’s coke production left a lasting legacy. It propelled the United States to the forefront of steel manufacturing. Even now, the Redstone coke ovens stand as monuments to this vital chapter in industrial America.

Colorado’s Industrial Heritage: The Role of Colorado Fuel and Iron

Colorado Fuel and Iron played a pivotal role in the industrial heritage of Colorado, particularly through the operation of the Redstone coke ovens. Founded in the late 19th century, this company was at the forefront of the steel production industry in the Western United States.

Establishment and Operations

Colorado Fuel and Iron, established as a powerhouse in the steel industry, quickly recognized the necessity of having a reliable coke source. The company’s strategic decision to build the Redstone coke ovens in 1899 transformed local coal into high-quality coke, essential for iron smelting and steel manufacturing.

Impact on the Local Economy

The operation of the Redstone coke ovens significantly boosted the local economy. It provided numerous jobs and supported ancillary businesses. The presence of these ovens marked a period of economic prosperity, as they supplied the essential materials needed by Colorado Fuel and Iron for their steel production facilities in Pueblo.

Connection with Western Pennsylvania

The establishment of the coke ovens under Colorado Fuel and Iron also created a link between Colorado and Western Pennsylvania, an area known for its rich history in coke production. This connection not only facilitated technological and resource exchange but also highlighted the widespread influence of coke production on the steel industry nationally.

Colorado Fuel and Iron’s management of the Redstone coke ovens underlines the significance of industrial synergy in America’s economic expansion. Their role in harnessing natural resources and transforming them into vital industrial commodities was crucial in positioning the United States as a leader in the global steel market.

The Decline of the Coke Industry and Redstone Ovens

The once-thriving coke industry began to falter in the early 20th century. Technological advancements and alternative fuels led to a decline in coke demand. This shift had a pronounced impact on places like Redstone, Colorado. By 1909, the Redstone coke ovens had suspended operations. This suspension marked a significant downturn in the local economy.

The decline was part of a broader trend affecting the coke industry across the United States. As industries adopted new technologies, the need for coke diminished. The introduction of natural gas and electricity as energy sources reduced reliance on coke for smelting and heating purposes.

The Redstone ovens, once bustling with activity, stood idle. Over time, they faced deterioration. Without maintenance, these historical structures suffered from the harsh Colorado weather. This physical decline mirrored the fading significance of coke in industrial processes.

Despite this downturn, the legacy of the coke era still echoes in Redstone. The structures remind us of a time when coal and coke were vital to America’s industrial growth. As interest in industrial heritage grows, these ovens have gained attention as important historical sites.

Preservation Efforts: Restoring the Redstone Coke Ovens

As time passed, the Redstone coke ovens fell into disrepair. Yet, recognizing their historical value, preservation efforts began. In 2011, a remarkable project took place aimed at halting further deterioration. This section explores the restoration of these industrial landmarks.

Initial Assessment and Challenges

Before the restoration could begin, experts assessed the ovens’ condition. Weather and time had taken a toll, leaving many ovens unstable. The challenge was to reinforce them without altering their historic character.

Restoration Process

The restoration involved careful planning and delicate work. Teams stabilized the structures, using materials that matched the original construction. They fixed cracks and rebuilt sections that had fallen away. The aim was to make the ovens safe for visitors while preserving their authenticity.

Community Involvement and Funding

Local communities rallied to support the preservation project. Fundraising events and grants helped finance the restoration. This initiative showed local pride in the area’s industrial heritage. It also underscored the importance of preserving historic sites.

The result of these efforts is a preservation success story. Today, the Redstone coke ovens stand as a testament to the region’s past. They continue to inspire those who visit, bridging the gap between history and the present day. These preservation efforts ensure that the ovens will be appreciated for generations to come.

Planning Your Visit: How to Get to the Redstone Coke Ovens

Visiting the Redstone Coke Ovens is an opportunity to connect with Colorado’s industrial past. If you plan to see these historical structures in person, here’s how to get there.

First, set your GPS for Redstone, Colorado. This charming town is the gateway to the ovens. From the central town area, look for signs pointing towards Highway 133. The ovens are located on the west side of this highway, about 18 miles south of another picturesque town, Carbondale.

Access to the site is straightforward. There’s a designated parking area close to the highway. Once parked, you’ll find marked pathways leading to the ovens. These trails are well-maintained and suitable for most visitors.

As you approach the site, the distinct dome shapes of the Redstone Coke Ovens emerge against the mountain scenery. It’s a short walk from the parking area to the ovens, making it an accessible adventure for anyone interested in history and industrial heritage.

Remember to bring a camera. The unique architecture of the ovens, paired with the natural beauty of the surroundings, makes for striking photographs. And while you’re there, take a moment to imagine the bustling activity that once surrounded these now-peaceful ruins.

Whether you’re an industrial history enthusiast or just looking for a unique day trip, the Redstone Coke Ovens offer a glimpse into a bygone era that shaped the very foundation of America’s steel industry.